Brake Repair, Service, and Inspections in San Antonio, TX

If you are searching for brake repair in San Antonio, you usually want one thing first: verified answers about what is making your car feel unsafe, noisy, or unstable under braking. At Auto Service Experts, we use a diagnostic-first process that measures brake wear, verifies hydraulic pressure, and confirms ABS data before we recommend parts. This way, you understand what your vehicle needs and why.

Auto Service Experts is located at 13050 San Pedro Ave, San Antonio, TX 78216. We help drivers across San Antonio get clear brake answers, then dependable repairs that hold up.

Trusted Brake Repair & Service For 20+ Years

Shop & Mechanic Certifications & Professional Recognitions

- ASE Master Certified Technicians (National Institute for Automotive Service Excellence)

- AAA Approved Auto Repair Facility

- BBB Accredited Business (A+ Rating)

- RepairPal Certified Facility

- TechNet Professional Auto Service Center

- NAPA AutoCare Center

- Dealer-quality repair without dealer pricing

- OEM & factory quality parts

- Auto AC EPA Section 609 MVAC Certification

- Complete 3 Year / 36,000-mile warranty on brake replacements

- Same-day brake service when available

- ASE Certified Brake Repair Specialists

- FREE diagnostics with approved repair

- Complimentary Shuttle service for 5 mi radius

Common Brake Problems We Diagnose

Car Shakes When I Brake

Brake vibration is usually caused by rotor variation or uneven clamping force. When the shake happens only during braking, the source is typically within the brake system rather than the tires.

What you feel: steering wheel shimmy at highway speeds, pedal pulsation, or a vibration that fades when you release the brake.

Common Verified Causes

- Rotor thickness variation from heat cycling

- Rotor runout caused by rust or debris between hub and rotor

- Improper wheel torque distorting the rotor

- Sticking caliper slides creating uneven pad pressure

- Suspension looseness amplifying braking load transfer

How repeat failures are prevented

We measure rotor thickness and runout with precision tools, clean hub mating surfaces, torque wheels to specification, verify caliper movement, and inspect supporting suspension components. By correcting the mechanical source of variation, we prevent repeat vibration after brake replacement.

Learn more on the dedicated diagnostic page: Car shakes when I brake

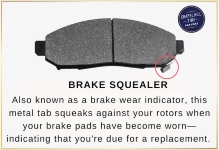

Squeaking Noise When Braking

Brake squeal is usually a friction or hardware issue. While temperature and humidity can affect noise, persistent squeaking indicates it is time to inspect.

What you hear: high-pitched squeal at low speed, first stop of the day, or light pedal pressure.

Common verified causes:

- Pads worn near the wear indicator

- Glazed pads or rotors

- Missing or bent anti-rattle hardware

- Incorrect pad material for the application

- Caliper hardware corrosion causing vibration

How repeat failures are prevented

We measure pad thickness, inspect hardware fit, service the contact points correctly, and confirm rotor finish. When appropriate, we install matched pad and rotor materials that reduce noise while maintaining stopping performance.

Learn more on the dedicated diagnostic page: Squeaking noise when braking

Brake Pedal Goes to the Floor or Is Very Hard to Press

A low, sinking, or unusually hard pedal indicates a hydraulic or power-assist issue. We verify whether pressure is being lost or assist is reduced before recommending repairs.

What you feel (soft or sinking pedal): increased pedal travel, a spongy feel, or a pedal that slowly sinks at a stop.

Common verified causes of a soft pedal:

- External leak at a caliper, hose, line, or wheel cylinder

- Internal master cylinder bypass

- Air in the system from a leak or improper bleeding

- Rear drum adjustment issues on vehicles that still use drums

- ABS hydraulic unit concerns on some platforms

What you feel (hard pedal): very firm pedal with reduced stopping assist, especially at low speed or during repeated braking.

Common verified causes of a hard pedal:

- Brake booster failure or internal diaphragm leak

- Vacuum supply problem from engine or vacuum hose

- Restricted brake line or collapsed hose

- Hydraulic restriction in ABS unit on some platforms

How repeat failures are prevented

We inspect for hydraulic leaks, verify master cylinder sealing, test brake booster assist and vacuum supply, confirm proper bleeding method, and validate rear brake adjustment and operation. By separating hydraulic pressure loss from power assist loss, we prevent unnecessary part replacement.

Learn more:

- Soft brake pedal or sinking pedal diagnosis

- Hard brake pedal diagnosis

Brake Warning Light on Dashboard

A brake warning light usually indicates a hydraulic, parking brake, or ABS concern. We verify which system triggered the light before recommending any repair.

What you see: red brake light, ABS light, traction control light, or a message related to braking performance.

Common verified causes:

- Low brake fluid due to pad wear or a hydraulic leak

- Parking brake switch or adjustment concern

- Hydraulic pressure imbalance between circuits

- Wheel speed sensor signal fault

- ABS module or communication issue after power or voltage concerns

How repeat failures are prevented

We inspect brake fluid level and condition, check for external leaks, verify parking brake switch operation, scan ABS and stability control modules for stored codes, and confirm power and ground integrity. By identifying whether the warning is hydraulic or electronic in origin, we prevent unnecessary part replacement.

Learn more on the dedicated diagnostic page: ABS warning light diagnostics

ABS Light On but Brakes Still Work

If the ABS light is on but the brakes still work, the base hydraulic system is usually functioning while anti-lock control may be disabled. The cause of the warning still needs verification.

What you notice: the ABS light stays illuminated, sometimes along with a traction control or stability control light, yet the pedal feel and stopping distance seem normal during everyday driving.

- The standard hydraulic braking system is functioning

- The ABS system has detected a fault in a sensor, circuit, or control module

- Anti-lock intervention during hard or slippery stops may be limited

Common verified causes:

- Wheel speed sensor signal dropout or erratic reading

- Damaged or corroded tone ring

- Wiring concern near the wheel or connector

- Wheel bearing play affecting encoder accuracy

- ABS module power, ground, or communication fault

- Low system voltage affecting module operation

How repeat failures are prevented

We scan for stored ABS codes, compare live wheel speed data while driving, verify power and ground integrity, inspect sensor wiring routing, and confirm the fault under the same conditions that triggered the light. By verifying the exact signal or circuit failure, we prevent replacing sensors or modules unnecessarily.

Learn more on the dedicated diagnostic page: ABS warning light diagnostics

How Much Brake Pad Thickness Is Safe?

Brake pad thickness determines how much safe stopping material remains. The correct timing depends on measurement, driving conditions, and wear pattern.

What we measure: pad thickness in millimeters at each wheel, inner and outer pad comparison, and overall wear pattern.

General safety guidelines:

- 10–12 mm: typically new pad thickness on many vehicles

- 6–8 mm: moderate wear, usually still serviceable

- 4–5 mm: planning stage, especially if driving conditions are severe

- 3 mm or less: commonly considered replacement range by many manufacturersSave

However, thickness alone is not the only factor. Uneven wear, heat cracking, glazing, or caliper binding can require service sooner even if some material remains.

Common verified reasons pads wear faster than expected:

- Sticking caliper slides or pistons

- Aggressive stop-and-go driving conditions

- Towing or heavy vehicle load

- Low-quality friction material

- Parking brake drag on rear pads

How repeat failures are prevented

We measure both inner and outer pads, confirm caliper movement, check rotor condition, and verify there is no drag or hardware issue accelerating wear. By basing recommendations on actual measurements instead of visual estimates, we help you plan service at the right time.

Learn more on our measurement-based Brake system inspection

How We Diagnose Brake Problems in San Antonio

We follow a verification sequence so the diagnosis is repeatable:

- Confirm the concern on a controlled road test.

- Measure pad and rotor condition, including thickness and wear pattern.

- Check rotor runout and hub surface condition.

- Inspect caliper slides, pins, boots, and bracket hardware.

- Verify brake fluid condition and check for leaks.

- If the lights are on, scan ABS for codes and view live wheel speed data.

Because the braking system blends friction, hydraulics, and electronics, this step-by-step approach helps prevent guesswork.

How to Prevent Repeat Brake Failures

Repeat brake issues are usually caused by an uncorrected root cause. Therefore, we focus on:

- Correct wheel torque and clean hub mating surfaces

- Complete hardware service, not pads only

- Brake fluid service when the moisture content is high

- Caliper slide lubrication with the correct materials

- Proper bedding procedure so that friction transfer is stable

- Having a brake inspection by a certified mechanic at regular intervals also helps to catch minor problems before they become larger ones.

Following a few driving and brake service/maintenance tips helps prevent major repairs due to unnecessary damage to the system. See our Auto Repair Blog for helpful advice on this topic and much more!

When a Warning Light or Data Code Matters

Your vehicle is equipped with a dashboard brake service/repair warning light that alerts you to problems in the braking system. Brake and ABS lights can point to low fluid, hydraulic imbalance, sensor signal issues, or module communication faults. Instead of replacing parts based solely on a code description, we verify the input and output. That means checking wheel speed sensor signals, power and ground integrity, and ABS command behavior.

Internal link: ABS warning light diagnostics

Brake Problems? Come see the certified brake specialists at Auto Service Experts.

Get Directions for Brake Repair in San Antonio

Auto Service Experts

📍 13050 San Pedro Ave, San Antonio, TX 78216

📞 (210) 495-6688

⏰ Mon-Fri: 8:00 AM – 6:00 PM

Serving North San Antonio, Stone Oak, Redland Oaks, Thousand Oaks, Encino Park, Hollywood Park, Hill Country Village, and surrounding neighborhoods.

See why our customers trust Auto Service Experts with their family’s safety!

⭐⭐⭐⭐⭐ 4.7 rating from 309+ verified reviews – Read All 300+ Reviews on Google

Frequently Asked Questions – San Antonio Brake Repair Shop

How do I know if my brakes are actually worn out?

Pad thickness and rotor measurements determine wear. We confirm numbers before recommending replacement.

Can rotors look fine but still cause vibration?

Yes. Runout and thickness variation can exist even when a rotor looks normal.

Why does my car squeak only at low speeds?

Light pressure can excite the pad and hardware vibration. We inspect pad material, shims, and hardware fit.

What does it mean if my brake pedal sinks at a stoplight?

It often points to hydraulic pressure loss, such as an internal master cylinder bypass or a leak.

Does brake fluid really matter?

Yes. Moisture lowers the boiling point and can affect pedal feel. Testing fluid condition helps prevent repeat issues.

Can ABS problems change how the pedal feels?

On some vehicles, ABS hydraulic unit issues can affect pedal feel. We verify with scan data and pressure behavior.

Should pads and rotors be replaced together?

Not always. We measure rotors and decide based on thickness, runout, and surface condition.

How long does a brake inspection take?

Most inspections can be completed the same day. The time depends on whether we need road testing and measurements on all four corners.

What is the next step if I want this checked?

Call Auto Service Experts, use the text button on mobile to send us a text, or schedule service online now.

Have Automotive Questions?

Call 210-495-6688 now to speak with an ASE Automotive Service Professional.

Brake Job by Auto Service experts Mechanic

ASE Certified automotive technician Roman Oliveras replaces pads and rotors in order to restore reliable, smooth vehicle stopping power.

Custom machine work to replace rear drum brakes on a 1974 Chevy K5 Blazer with rear disk brakes from a 2005 Chevy Avalanche 4×4.

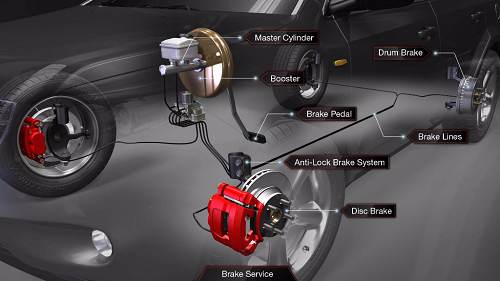

Braking System Operation & Service Recommendations

Modern braking systems do more than provide stopping power. They work together with stability control, traction control, and ABS to maintain vehicle control and safety. When a braking component fails, it can affect multiple systems at once, which is why we verify full system interaction during diagnosis rather than focusing on a single part.

Disc brake systems use rotors, calipers, and brake pads working together to slow the vehicle. When the brake pedal is pressed, hydraulic pressure pushes the pads against the rotor, creating controlled friction that reduces wheel speed and brings the vehicle to a stop.

Brake pads use friction material to slow the rotor when hydraulic pressure is applied. As the material wears down, braking performance decreases, and noise may develop as wear indicators or metal backing plates contact the rotor. Replacing worn pads at the proper time helps protect the rotors and maintain consistent stopping performance.

Brake rotors must be inspected for thickness, surface condition, and heat damage during service. Over time, they can develop vibration, cracking, scoring, or wear below factory specifications. When this happens, resurfacing may not be possible, and replacement is required to restore proper braking performance. Installing new pads on worn or damaged rotors often causes noise, vibration, and reduced braking performance, which is why we verify rotor condition before recommending repairs.

Auto Service Experts Brake Shop San Antonio

At Auto Service Experts, brake service begins with a comprehensive diagnostic evaluation designed to verify system condition before any parts are recommended. We assess component wear, hydraulic operation, rotor condition, and overall system interaction to identify the true cause of braking concerns rather than treating symptoms alone.

Brake pad materials are carefully selected based on vehicle design, driving habits, and manufacturer specifications to maintain consistent stopping performance, reduce noise, and ensure long-term durability. Many repairs include CarQuest Wearever ceramic or semi-metallic pads chosen for predictable braking response and extended service life.

Our diagnostic-first approach focuses on restoring proper braking performance through accurate testing, professional installation, and repairs designed for long-term reliability.

Every brake repair recommendation is based on verified testing and real inspection results, helping you understand exactly what your vehicle needs and why, so you can make confident decisions about your safety and long-term reliability

Our professional mechanics are committed to providing exceptional service.

Our professional technicians approach brake service with a diagnostic-first mindset focused on accuracy, safety, and long-term reliability. Every brake inspection includes careful evaluation of wear components, hydraulic operation, and system interaction to ensure the correct repair is recommended the first time. Rather than relying on assumptions, we verify conditions through testing and measurement, helping drivers understand what is happening, why it matters, and what will restore proper braking performance.

Brake Inspections

Regular brake inspections help maintain consistent stopping performance and overall vehicle control. As components wear over time, braking response can change, so routine inspections help identify potential issues early before performance is affected. Signs such as reduced braking performance, unusual noises, a hard brake pedal, or a soft, spongy brake pedal indicate that the system should be evaluated promptly.

During an inspection, critical components are carefully checked to verify proper operation, identify wear, and confirm hydraulic system performance. This diagnostic-first approach helps protect rotors, maintain reliable braking performance, and reduce the risk of more costly repairs. At Auto Service Experts, our ASE-certified technicians follow verified inspection procedures designed to confirm system condition and ensure repairs meet our standards, backed by a 3-year/36,000-mile parts-and-labor warranty.

Our Complete Brake Check Includes the Following Inspections:

- Fluid Condition (when fluid is exposed to moisture, it becomes acidic and can damage the seals and ABS module).

- Lines

- Pads

- Calipers

- Emergency Brake Adjustment

- Hoses

- Rotors

- Check for leaks in:

- Fitting Hoses

- Junction Blocks

- Lines

- Master Cylinder

- Modules

Brake Job on 2012 Dodge Ram 350

Why Routine Service and Inspections are Necessary

Modern braking systems have improved significantly, but they still require regular inspection to maintain proper performance. A thorough annual inspection should include removing the wheels and evaluating internal components that are not visible during a basic check. While certain symptoms clearly indicate the need for service, following the manufacturer’s maintenance schedule helps identify potential issues early, helping prevent unnecessary repairs and inconvenience.

Several factors influence brake system wear and overall performance, including driving habits and operating conditions. Frequent stop-and-go traffic, excessive pedal pressure, and aggressive braking can accelerate component wear. Replacing brake pads before they wear down to metal helps prevent damage to rotors or drums, reducing the risk of more costly repairs and maintaining consistent braking performance.

Proper auto suspension system maintenance. Suspension condition also affects braking performance. Worn shocks or struts can increase stopping distance because the braking system relies on consistent tire contact with the road and proper weight distribution. As suspension components wear, wheel control becomes less stable, and braking efficiency can be reduced. In some cases, driving at highway speeds with worn shocks can significantly increase stopping distance, which is why suspension inspection is an important part of evaluating overall braking performance.

Diagnostic Benefits of Regular Brake Inspection

- Peace of mind – Protect your safety and that of your family.

- Regular brake inspections allow developing issues to be identified through measurement and system evaluation before they affect braking performance.

- By verifying pad thickness, rotor condition, hydraulic operation, and overall system interaction, potential problems can be addressed early rather than after symptoms worsen.

- This diagnostic-first approach helps maintain consistent stopping performance, protects critical components from unnecessary wear, and supports long-term reliability by preventing avoidable repairs.