Dodge Charger Fuel Gauge Not Working After Fuel Pump Replacement: A BCM Trivia Case Study (San Antonio)

Introduction

A Dodge Charger came into Auto Service Experts at 13050 San Pedro Ave, San Antonio, TX 78216 after another shop replaced the fuel pump and repinned the connector because of overheating at the pigtail.

The customer’s complaint was simple: the fuel gauge worked before the repair, then quit right after. The scan tool showed both fuel level signals stuck high, and the BCM would not let the fault clear.

Trivia Question

A fuel gauge quits after a fuel pump install and connector repin. Fuel Level Sense 1 and 2 both peg high (4.98 V), and the BCM stores hard fuel level circuit faults. Which of the following can cause this exact symptom set?

A. A connector repin mistake or terminal issue that puts a fuel level signal in the wrong cavity

B. An open or unstable fuel level sensor return (signal return) that makes the module see “circuit high.”

C. A failing Body Control Module (BCM) input stage that falsely flags the fuel level circuits as high or open

D. All of the above

Answer

D. All of the above.

That’s why this case study matters. The symptoms can look identical, so we built a quick, clean test path to find the real root cause.

The Diagnostic Story, Step by Step

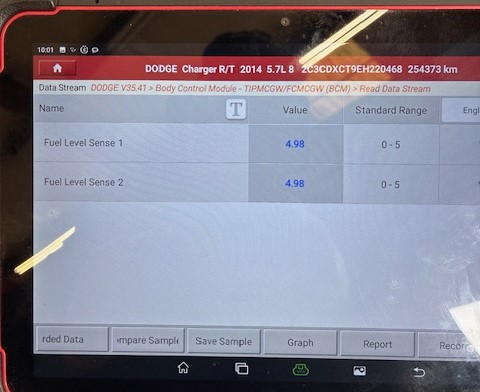

Step 1: Confirm the problem in live data

We started where the vehicle was “talking” the loudest: the scan tool.

What this told us:

- Both fuel level signals were behaving the same way at the same time.

- That immediately points toward a shared cause (wiring strategy, return, connector, or module logic).

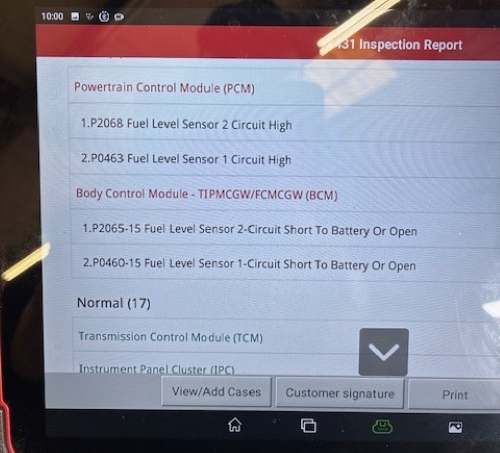

Step 2: Check which module is complaining and how hard the fault is

Next, we pulled the codes and checked which module was storing them.

What this told us:

- The BCM was storing the hard faults.

- Clearing in one module but not the other is a clue: sometimes the “real decision maker” is the BCM.

If your dash is throwing warning lights or stored faults, our check engine light diagnostics in San Antonio can pinpoint the real cause before parts get replaced unnecessarily.

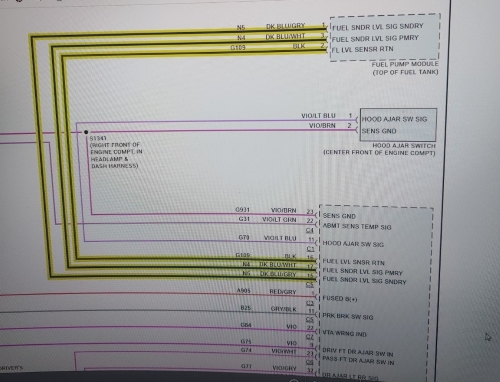

Step 3: Lock down the wiring strategy before touching anything else

Fuel level circuits are easy to miswire after a pigtail repair, so we anchored our plan to the diagram and pin ID.

What this told us:

- Exactly which circuits were Fuel Level Signal Primary, Fuel Level Signal Secondary, and Fuel Level Sensor Return.

- Which cavities could be confused when someone is repinning quickly.

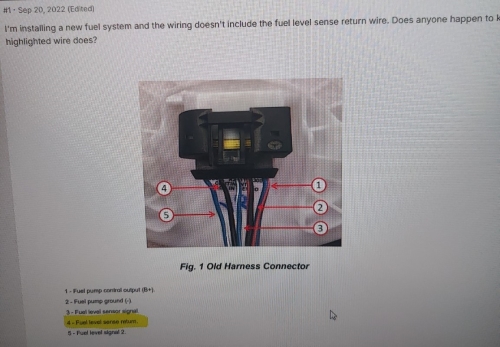

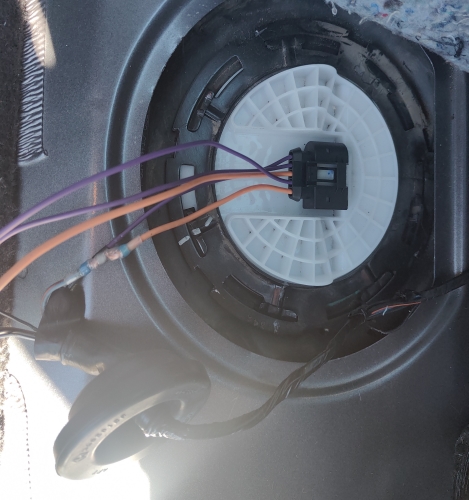

Step 4: Inspect the repin and the connector work up close

We don’t guess. We verify the actual connector in our hands.

What this told us:

- The repin work needed to be treated as a suspect, but we still had to prove it was the cause.

Step 5: Tank-side testing and the “wait…why is this showing 13.47 volts?” moment

With the tank access open, we tested right at the connector.

What this told us:

- We had an abnormal voltage reading that could easily look like a short to the battery.

- But voltage on a meter is not the same thing as a circuit that can deliver current.

This is a great example of why auto electrical repair and wiring diagnostics matter, because a fuel gauge issue can look like a bad pump when the real problem is upstream in the control circuit.

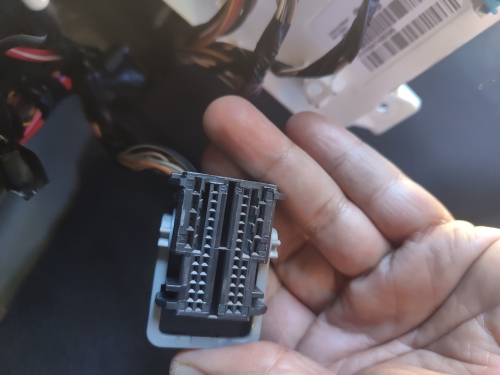

Step 6: Prove the harness isn’t shorted between the BCM and the fuel pump module

This is the part that keeps the case study honest.

We back-probed at the BCM and verified the same fuel level circuits end-to-end.

What we proved:

- No short circuit between the BCM and the fuel pump module.

- At that point, a BCM input fault moved from “possible” to “probable.”

Step 7: The fix and the verification

We replaced the BCM (Body Control Module) and confirmed normal operation.

What this case teaches

When a fuel gauge fails after a fuel pump install, it’s tempting to blame the pigtail every time.

Sometimes that’s right.

But in this Dodge Charger case, we verified the wiring path and found no short between the BCM and the fuel pump module. Replacing the BCM fixed the issue.

Need help in San Antonio?

If your fuel gauge stopped working after a fuel pump replacement, we can test the circuit and module logic properly.

Get Directions for Expert Diagnostics or Electrical Repair In San Antonio!

Auto Service Experts

📍 13050 San Pedro Ave, San Antonio, TX 78216

📞 (210) 495-6688

⏰ Mon-Fri: 8:00 AM – 6:00 PM

Serving Stone Oak, Hollywood Park, Hill Country Village, and North Central San Antonio.

See what our customers say about our Auto Diagnostic service

⭐⭐⭐⭐⭐ 4.6 rating from 306+ verified reviews – Read All 300+ Reviews on Google